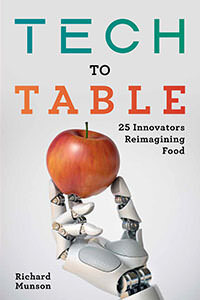

Coating Foods and Cutting Waste — Apeel Sciences

Jenny Du, James Rogers, and Louis Perez

James Rogers, Jenny Du, and Louis Perez want to cut food waste in half.

With PhDs in materials science and chemistry, they devise plant-based

coatings that double the shelf life of avocados, oranges, and other produce. “If we wasted less food,” they say, “we could feed more people. But

how to stop food from going bad?”

The problem of food loss, the scientists claim, is rather straightforward: “The two leading causes of produce spoilage are water loss and oxidation—that’s water evaporating out of the produce and oxygen getting in.” So the trio creates tasteless, odorless, invisible, and edible coatings—consisting of fatty acids and other organic compounds extracted from the peels and pulp of produce—that act as physical barriers to keep water in and oxygen out. To improve and market that innovation, in 2012 they formed Apeel Sciences, headquartered in a one-story warehouse in a new industrial park in Goleta, a vibrant community of technology upstarts near the University of California, Santa Barbara (UCSB).

Rogers initially thought he would use his doctorate to create a paint that converts the sun’s rays into electricity, providing less expensive power than photovoltaic panels; remembering his long hours testing alternative stains, he describes that period of his life as “watching paint dry.” One day while driving between the University of California’s labs in Santa Barbara and Berkeley, he marveled at the expansiveness of the Salinas Valley’s rich farmland but, while listening to a podcast about world hunger, wondered why so many people go hungry amid such food abundance. “The problem,” he eventually concluded, “came down to distribution. We couldn’t get the food that was being grown to where the people were who need to eat it. And so I was curious what precludes us from distributing food and it all comes down to the notion of perish- ability.” He decided to stall spoilage.

As a materials scientist, Rogers knew coatings protect steel from rust- ing, so he felt a similar barrier should retard the rate of food rotting. After jotting out a plan on a napkin, he phoned his mother and said, “Hey, Mom, I got this idea for a company,” to which she responded: “That sounds really nice, but you don’t know anything about fruits and vegetables.”

Rogers admits Mom was right, so he began to read up on plant biology and wrote a proposal to the Bill & Melinda Gates Foundation to reduce postharvest food loss in developing countries that lack access to refrigeration. Its $100,000 grant in 2012 allowed him to join with two other researchers—Jenny Du and Louis Perez—and start Apeel Sciences.

Perez obtained his doctorate in materials from UCSB and focuses on research and development, engineering, and software, having gained six patents for technology he developed at Apeel. Du grew up in Canada in what she calls a “super blue-collar family.” Her parents fled Vietnam by boat in the late 1970s, and even though her father reached only the sixth grade, they pushed her to study engineering chemistry at Queen’s University in Ontario, Canada, and then obtain a PhD in chemistry from UCSB. None of Apeel’s founders, she observes, “were in fresh fruit or vegetables or food or plants to begin with, at all.”

Perez, Du, and Rogers say the harder transition was from academics to entrepreneurs, from advancing a concept to producing a product. Trained as scientists, they admit, they’re “pretty married to the beauty of the idea, the elegance of the science and the idea, but then, to actually make it work in a business setting, that’s the first one percent. To actually carry over from . . . an idea into true innovation and application, requires a whole bunch of other stuff.” Rather than be locked into your original plan, they say, you have to “listen to the feedback from your customers, from your stakeholders, as to what might alternatively be possible or help it gain traction.”

To attack the problem of spoilage, Rogers, Du, and Perez advanced a straightforward-sounding idea: to produce coatings—what they call “protective peels”—that allow a variety of produce to stay fresh two to three times as long. Their challenges, however, were anything but simple—to invent the coatings, design an application process, make the technology affordable, and convince customers to use it.

Apeel’s founders take advantage of cutin, a natural sealant plants use to retain moisture, but they create proprietary mixtures of lipids and glycerolipids from the peels, seeds, and pulp of various fruits and vegetables that, when water starts evaporating, join together to build a film that traps moisture and rejects oxygen. “Part of [the mixture] really likes water, and part of it really doesn’t like water, which means you can get some limited solubility of that material in water,” the trio says. “Once they dry, then they have the ability to block water.”

Since different types of produce degrade differently, the innovators began investigating why a strawberry naturally lasts a couple of days while a lemon retains its fruitiness for several weeks. “Remarkably,” they say, “it’s not that they’re made of different things, but rather that the molecules on the surface of a strawberry are arranged dramatically differently than they’re arranged on a lemon.” Apeel’s challenge was to tailor its formulas for each type of produce in ways that augment the natural protective barriers of the vegetables and fruits. Although different plants offer richer sources of lipids, coatings can be made from any peels and seeds that remain unused after harvesting. “Essentially,” the founders say, “Apeel is cutting and copying from what the natural world is already doing,” and the start-up builds “a world that works with nature, not against nature.” Because “we use food to preserve food,” they conclude, both traditional and organic farmers can utilize Apeel’s products.

The young entrepreneurs recognize that humans have tried for centuries to protect fruits and vegetables, without much success. Medieval monks dipped apples in beeswax, a shield that made fruit look good for a short period but did little to retard dehydration and oxidation. The difference is that we now understand the detailed science of how produce ripens and rots.

“Produce is a living, breathing thing, even after it’s picked,” explain the founders. “The trick is to maintain as much moisture as possible and maintain a very delicate balance between the rate of oxygen getting in and the rate of carbon dioxide getting out. If you cut down the oxygen too much, the fruit won’t develop appropriately and it will develop off flavors, and if you don’t cut down the oxygen enough, you’ll have no impact.”

Apeel markets its product, called Edipeel, as a powder that its partners—fresh-food suppliers and retailers—mix with water and then spray, dip, or brush onto produce. “The result,” says Rogers, “is that we form this special structure, this special barrier, which mimics that structure which is employed by longer shelf life produce.” With oxygen repelled, the fruits and vegetables become less stressed, their metabolic rates slow, and they better defend themselves against biotic infections such as mold.

Apeel started with avocados, which ripen and brown quickly and often end up in trash bins. When coated and given a longer shelf life, the often-imported fruit can be transported by sea without refrigeration, rather than by air, thereby reducing greatly the product’s cost and carbon footprint. Rogers, Du, and Perez subsequently developed protective layers for limes, mandarins, oranges, and organic apples, but they have set their sights on all fruits and vegetables.

Initial customer reviews judge the edible “skin” to be tasteless and colorless, neither waxy nor greasy. Managers at Costco, Kroger, and other grocery stores say the coatings allow them to sell more fruits and vegetables, face lower waste-management costs, and suffer fewer customer returns. A former CEO of Whole Foods Market commented, “As a fresh grocer for over 40 years, I can truly say that I have never seen anything like Apeel, and I believe it has the potential for global impact on the food system.”

Consumers also appreciate the reductions in packaging waste. Responding to their pressure, Walmart in September 2020 ditched its plastic shrink-wrap around cucumbers; the giant food marketer estimates that coating rather than wrapping 100,000 cases of the vegetable removes the equivalent of 165,000 single-use plastic water bottles from landfills.

Initial reactions from investors also are impressive. Apeel raised $250 million in capital in May 2020, bringing its total valuation above $1 billion and making it another food-focused unicorn. Building on its early grant from the Gates Foundation, Apeel in late 2020 raised another $30 million to help smallholder farmers in remote locations, such as sub-Saharan Africa, obtain access to new markets and retail opportunities. Oprah Winfrey, one of the firm’s high-profile investors, comments, “I hate to see food wasted when there are so many people in the world who are going without. Apeel can extend the shelf-life of fresh produce, which is critical to our food supply and our planet too.”

Edipeel does not eliminate food waste. Rough handling or poor refrigeration can pierce the coating and expose fruits and vegetables to contaminants. Restaurant patrons also may not eat their helpings, and forgotten produce at the backs of refrigerators can decay over time. Yet Apeel claims to be “the only postharvest solution that creates an optimal microclimate inside every piece of produce, which leads to extended shelf life and transportability.”

Consumers enjoy fresher, better-tasting, and more nutritious produce. Distributors spend less on packaging and controlled-atmosphere storage. Grocery stores reduce their discards and thereby cut their costs.

Landfills with less organic wastes emit less greenhouse gases. Finally, by slashing food waste, the overall agricultural system expends less on water, wages, plastics, and chemical additives, as well as ensuring more food gets to more people.

Apeel’s cofounders expect that in twenty years, sophisticated coatings will almost eliminate food waste and increase food choices. “You’ll be able to walk into any corner store, any little bodega, any 7-Eleven, any mom-and-pop store,” they predict, “and be able to pick up a piece of produce that was grown by a small farmer on the other side of the world, and it will be better than any produce you’ve ever eaten in your life.”