Weeding Robotically: Eliminating Poisonous Herbicides on Farms

Jorge Heraud and Lee Redden, Blue River Technology—Spraying Precisely

To generations of farmers, chemicals seemed like the only plausible alternative to the back-breaking work of picking weeds and bugs off crops by hand. So it may be surprising that some of the most important recent technological developments in managing pests mark a return to that very method. But instead of human hands, technologists are taking advantage of robotic engineering, advanced sensors, and artificial intelligence to create giant weed-picking or precision-spraying machines.

Such innovation thrives because traditional synthetics have a “catastrophic impact” on human health and the environment. One systematic review found that “most studies on non-Hodgkin lymphoma and leukemia showed positive associations with pesticide exposure;” other researchers identified links between organophosphate insecticides and neurobehavioral ailments.

Since most pesticides drift, never reaching their targets, synthetic chemicals pollute waters, contaminate soils, destroy habitats, and reduce biodiversity. The United Nations reports that the loss of species and habitats, much of it caused by industrial agriculture, poses as much danger to life on Earth as does climate change. The U.S. Department of Agriculture estimates that 50 million Americans drink from groundwater contaminated by pesticides and other agricultural chemicals. The widespread use of synthetics also leads to resistant pests, raising fears of “superbugs” and prompting additional chemical applications.

Working with pesticides, moreover, is dangerous. The U.S. Environmental Protection Agency calculates that almost 20,000 farmworkers each year suffer acute pesticide poisoning, and their death rates exceed seven times that of other workers. The damage is more severe in developing countries, where the United Nations estimates 200,000 people die—and another 25 million agricultural workers experience unintentional poisonings—each year from toxic exposure to pesticides.

Farmers are not taking these risks without reason. Pesticides—including herbicides and insecticides—can prevent crop losses and save money. One study found that yields would fall 10 percent without the use of synthetic chemicals. Yet farmers are using these chemicals to tread water, not gain ground. In part because of pesticide resistance, pests and disease still destroy 30-40 percent of all crops, a figure that has remained constant since the 1940s when ranchers and farmers began to deploy agrichemicals.

Jorge Heraud and Lee Redden met as graduate students at Stanford University and envisioned robots spraying weeds precisely, helping farmers save money and reduce environmental threats. They called their start-up “Blue River” to signify the clean waterways that would result from cutting dramatically agriculture’s use of poisonous herbicides.

To reduce chemical use and increase sustainability, Heraud envisioned “mainstreaming artificial intelligence as an integral part of agriculture.” The biggest mega-problem facing farming, he says, “is how do we clean up our act, maintain scalability so that we can feed everybody—and even those who are to come—but do it in a sustainable way.”

“We could have gone in 1,500 different directions,” admits Heraud, but Blue River’s founders decided to concentrate on weeds, particularly those crowding cotton and soybeans. They called their new machine See & Spray.

Pulled behind a tractor like conventional spraying equipment, the 40-foot-wide robot uses thirty mounted cameras, supercomputing modules, and algorithms similar to facial recognition in order to distinguish crops from unwanted plants. The machine utilizes a database gleaned from taking and analyzing more than a million images, in different stages of growth, of pigweed, giant ragweed, cocklebur, or foxtail—to name a few common weeds—in order to recognize differences that might challenge the human eye. As the robot passes through a field at about seven miles per hour, its sharpshooting nozzles zap the identified weeds with a precise herbicide application about the size of a postage stamp that is tailored for the specific weed.

To recognize different crops and weeds requires deep learning, which didn’t exist when the pair started Blue River but is advancing rapidly with significant improvements in software and hardware. “Traditionally, we would have designed an algorithm by using visual cues to identify the 10 or 20 parameters that best distinguish crops from weeds,” says a Blue River vision engineer. “With deep learning, we can design a neural network that learns a million parameters to determine which are best for distinguishing crops from weeds. We do this by training the neural net with hundreds of thousands of examples from different farmers’ fields.”

In addition to being smart, the robot and its precision equipment must be rugged enough to withstand a farm’s heat and dust as well as the jostling through rutty fields. As one Blue River engineer states, “We have to design components that maintain a camera’s orientation to the crops to within a degree or two, all while taking a beating in day-to-day use. We found a lot of ways that didn’t work before finding the one that did.”

See and Spray’s precise applications save up to 90 percent compared to conventional herbicide spraying. Farmers enjoy reduced expenses, improved profitability, and fewer poisons leaching into the groundwater or streams.

Yet Heraud and Redden see a broader mission—to revolutionize weed control in a world of growing pesticide resistance. Industrial agriculture’s broadcast spraying of a limited number of herbicides has led to 250 species of resistant weeds that threaten to overrun farms. Blue River claims it gives growers a safer and more precise way to control unwanted plants.

The entrepreneurs also want to change the scale of farming. Rather than treat an entire field the same way with a one-size-fits-all approach, Heraud claims robots can nurture a specific plant with less costs to the farmer and damage to the environment. Blue River’s smart machines, he says, can “sense each individual plant, instantly determine everything about its health, structure and needs, and precisely apply the right amount of care.” With precision robots, he adds, farmers need fewer chemicals and smaller numbers of workers to perform the dirtiest and most dangerous jobs.

Although proud of their progress and prospects, the two recognized in 2017 that further success required turning “from a company that is a great engineering company to a company that also can manufacture reliable equipment, distribute it, support it, and grow the company in areas outside our expertise.” Their other option was to partner with someone who could, so they accepted a $305-million buy-out from Deere & Company, which committed to maintaining Heraud, Redden, and their team in Sunnyvale, yet time will tell if they retain their entrepreneurial spirit within a huge company.

Now with additional resources, Heraud hopes Blue River soon will integrate advanced technology into all farm equipment, including planters, sprayers, and harvesters, and he wants his ultra-precise approach expanded to fertilizers, insecticides, and fungicides. To be profitable and sustainable, he asserts, agriculture must embrace robots.

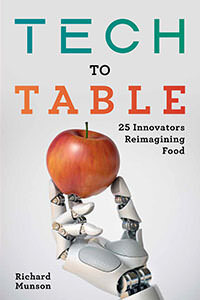

Read more about Heraud, Redden, agricultural robotics, and other farm and food entrepreneurs in Tech to Table: 25 Innovators Reimagining Food.